Adaptive compliant wing

An adaptive compliant wing is a wing which is flexible so that aspects of its shape can be changed in flight. Adaptive controlled wing – the wing of the aircraft, whose profile takes the form close to optimal for each given flight mode. The design of such a wing allows smoothly (due to flexible skin ) to deflect the nose and tail of the wing, thus changing the curvature along the span, depending on the height, flight speed and overload. The adaptive wing is intended mainly for multi-purpose and highly maneuverable aircraft. The wing elements are controlled by a highly automated electric remote variable system.

A variety of improving the aerodynamic quality of the wing is also a system of adaptive “slit” wing mechanization. It provides a smooth (within the required accuracy, maybe stepwise) change in the installation angles of the socks and flaps, depending on the angle of attack and the Mach number. However, this system allows for a discontinuous change in aerodynamic derivatives in the entire range of parameters, in contrast to the adaptive wing. Work is also underway on the implementation of a continuous flow around the surfaces of mechanization by changing the curvature of the elements of the slot mechanization. Due to the simplified kinematics of extending the flaps, adaptive wing mechanization is attractive because it eliminates the use of complicated configurations and increases the weight of the wing guided rails, and also reduces the loss of bearing properties for balancing.

Appointment

Effective flight in the atmosphere requires different aerodynamics from the apparatus, depending on flight speed, flight mode. The classical approach to the design of new aircraft now allows only slightly (no more than 1-2%) to improve the aerodynamic quality and improve takeoff and landing characteristics. Mechanization of the wing in the form of simple deflectable socks and tails of the profile or change of sweep does not allow to achieve high values of the maximum lift coefficient under varying operating conditions.

Therefore, in recent years, in connection with the development of the technical base and the emergence of new aviation materials, more and more attention is being paid to the possibility of improving the aerodynamic characteristics of the aircraft by changing the geometry of the wing depending on the flight mode — the use of an adaptive wing. Adaptation of the aircraft carrier system can be carried out by changing the span and sweep of the wing, as well as the shape, curvature and thickness of the profile.

It is intended to use elastic outer casing, and the power frames inside this casing will be adapted to smoothly change its own geometry.

An important distinctive feature of such a wing is the preservation of the smoothness of its profiles during deformation of the median surface. Reduced resistance can be achieved in two ways. Firstly, due to the optimal change depending on the flight mode of deformation of the median surface. This allows cruising modes to make the wing almost flat, which reduces the resistance at zero lifting force, and during maneuver – optimally deformed with circulation distribution along the wing span close to elliptical, which reduces inductive resistance. Secondly, at large angles of attack, in places of fracture of the upper surface of the wing, when a conventional mechanization deviates, local separation of the flow occurs.. The use of adaptive wing socks with a large relative chord and flexible upholstery can solve this problem.

The deviation of moving elements while maintaining the smoothness of its contours according to some law, selected on the basis of experimental and calculated research, allows redistributing the pressure on the wing surface in such a way as to prevent the flow from stalling or significantly weaken its development in the selected flight mode. As a result, the boundary of the occurrence of shaking and buffering is shifted to large angles of attack, increasing the efficiency of turning surfaces operating in the mode of controls. During the maneuver, by preventing flow separation, the adaptive wing gives a tangible gain in aerodynamic quality.

If a change in the shape of an adaptive wing is subordinated to conditions under which the critical point in each section of the wing shifts to the toe of the profile, and the velocity circulation distribution over the span becomes elliptical, then at a selected lift coefficient value, the drag coefficient is minimal. In the first case, the rarefaction peaks in the vicinity of the leading edge, which on a conventional wing lead to a flow angle and loss of suction force, that is, an increase in resistance, decrease. When the second condition is met, the inductive resistance is minimized.

The deviation of the elements of the adaptive wing, carried out so that the center of pressure of the aerodynamic forces acting on the aircraft does not change its position, makes it possible to directly control the aerodynamic lift.

The modern technological base and the development of aviation materials make it possible to ensure the creation of actuating mechanisms for controlling the flow of a carrier system without using the resources of a marching power plant, based on autonomous sources of compressed air. Structural and technological basis of jet control systems can be active gas-dynamic actuators that operate on the principle of parallel injection using gas dynamic pistons.

Wrap Management

One of the ways to improve aerodynamic quality in cruise flight mode and improve the take-off and landing characteristics of an aircraft is to actively control the flow around aerodynamic carriers and control surfaces using energy methods: boundary layer control, blowing the jets on the elements of the wing and landing mechanization, jet and jet flap. Controlling the boundary layer by its suction from the wing surface, tail assembly and engine nacelle is an effective way to reduce friction resistance (by artificial laminarization of the flow). In addition, blowing the boundary layer can provide a continuous flow around the wing at high angles of attack and large angles of deflection of the elements of wing mechanization and thereby increase the maximum lift coefficient and critical angle of attack.

Examples of implementation

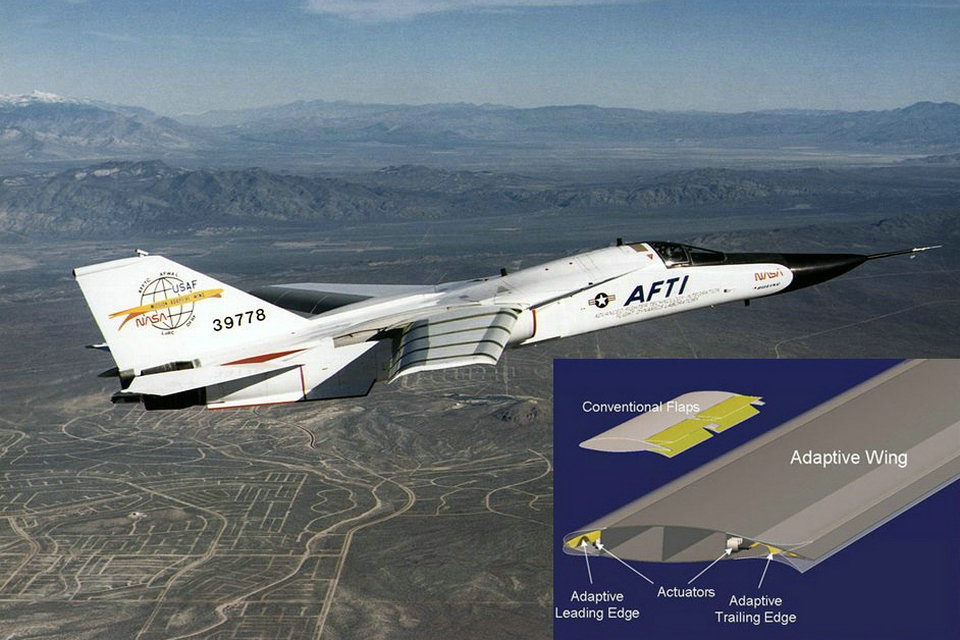

Development of an adaptive wing capable of changing the curvature in flight while maintaining smooth contours was started in the USA in 1979 using the AFTI (Advanced Fighter Texnology Integration) program implemented by NASA and the USAF. This wing was first installed in the 1980s on an experimental F-111 aircraft. The change in the curvature of the wing in flight was made depending on the height of the flight, the Mach number, the angle of sweep, and the required lifting force. The goal was to ensure the smallest drag coefficient at each value of the lift coefficient. The front and the tail parts of the wing with a flexible skin allowed to smoothly change the curvature of the wing, so that the polar would be the envelope of the polars corresponding to different wing configurations. Then it required huge capital expenditures and the most complicated constructive decisions. At present, due to the advent of elastic composite materials, the situation has become simpler.

Later, starting in 1987, similar studies were carried out in Airbus Industrie when developing a wing with controlled curvature for the A330 and A340 aircraft. It was assumed that the control of the curvature of the wing due to the automatic change of the angles of deflection of two pairs of flaps and aileronsfor each half wing, it should provide the optimum curvature of the profile for each flight mode, as a result of which a significant improvement in the aerodynamic quality should be achieved in the cruising mode with an increased lift value. Tests of wing models in a wind tunnel showed that the aerodynamic quality of the wing with controlled curvature is only ~ 1.5% higher than normal. Therefore, the researchers came to the conclusion that the additional mechanization and complexity of the curvature control system, as well as an increase in the mass of the structure, do not justify a slight improvement in the fuel efficiency of the aircraft.

Nevertheless, in 2008 – 2012 years of continued research on the project SADE (SmArt High Lift Devices for Next Generation Wing) of the 7th European Framework Program. The objective of the project was to study an adaptive gapless leading edge, an adaptive smoothly deflectable trailing edge to increase the aerodynamic quality of the next generation aircraft wing while significantly reducing the weight of the structure, reducing noise during takeoff and landing modes, and increasing fuel efficiency.

The latest modification of the aircraft Boeing 787 Dreamliner applied a change in the curvature of the rear of the wing profile on the takeoff and landing. In this case, with the release of flaps, their roofs are also deflected, which will not only increase the efficiency of flaps, but also the bearing capacity of the main part of the wing due to the increased curvature of its profile.

In the United States, work is underway to create an adaptive wing by FlexSys Inc., US Air Force Research Laboratory Russian. according to the program of the active aeroelastic wing of Boeing X-53 Active Aeroelastic Wing.

An adaptive compliant wing designed by FlexSys Inc. features a variable-camber trailing edge which can be deflected up to ±10°, so that it acts like a flap-equipped wing, but without the individual segments and gaps typical in a flap system. The wing itself can be twisted up to 1° per foot of span. The wing’s shape can be changed at a rate of 30° per second, which is ideal for gust load alleviation. The development of the adaptive compliant wing is being sponsored by the U.S. Air Force Research Laboratory. Initially, the wing was tested in a wind tunnel, and then a 50-inch (1.3 m) section of wing was flight tested on board the Scaled Composites White Knight research aircraft in a seven-flight, 20-hour program operated from the Mojave Spaceport. Control methods are proposed.

Adaptive compliant wings are also investigated at ETH Zurich in the frame of the Smart airfoil project.

In Russia, examples of the use of adaptive take-off and landing mechanization on the wing of a passenger aircraft are unknown, studies to assess its effectiveness began at TsAGI more than 20 years ago. An adaptive deflectable toe of the wing with a flexible skin was used on an experienced deck fighter Su-33UB.

Source from Wikipedia